Restoring 1220, 1225 and 1230 keypad: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| (6 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

'''''See also →''' [[Rebuilding 1230 keypad using 3D printer]]'' | |||

==Description== | ==Description== | ||

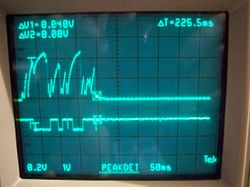

[[Image:Bounce(1).jpg|thumb|left|250px|(Pic1) "Bouncing" switch, the second trace is the signal coming out of a | |||

[[Image:Bounce(1).jpg|thumb|left|250px|(Pic1) "Bouncing" switch, the second trace is the signal coming out of a [[Schmitt trigger]].]] | |||

[[Image:Bounce(2).jpg|thumb|right|250px|(Pic2) Registered presses being sent to the LA.]] | [[Image:Bounce(2).jpg|thumb|right|250px|(Pic2) Registered presses being sent to the LA.]] | ||

*The [[1220]], [[1225]] and [[1230]] have a keypad interface for controlling them. The switches are tactile switches with a small spring. Over time they start to become extremely "bouncy". This is due to a number of factors, some including corrosion and weakening springs. Over time this will lead to problems such as the | *The [[1220]], [[1225]] and [[1230]] have a keypad interface for controlling them. The switches are tactile switches with a small spring. Over time they start to become extremely "bouncy". This is due to a number of factors, some including corrosion and weakening springs. Over time this will lead to problems such as the keypad being less responsive and the analyzer registering multiple presses. | ||

< | |||

Picture 1 shows what the keypad is registering. | |||

<div style="clear: both"></div> | |||

==Fix== | ==Fix== | ||

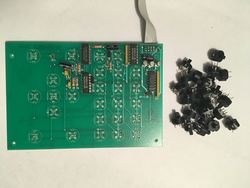

[[Image:Bounce(4).jpg|thumb|left|250px|(Pic3) Keypad switches]] | [[Image:Bounce(4).jpg|thumb|left|250px|(Pic3) Keypad switches]] | ||

[[Image:Bounce(5).jpg|thumb|right|250px|(Pic4) Keypad switches]] | [[Image:Bounce(5).jpg|thumb|right|250px|(Pic4) Keypad switches]] | ||

*The switches that the keypad uses are still being manufactured today. They are C&K D6L90F1LFS | * '''WARNING!''' When taking the analyzer apart, users are at their own risk! The inside contains lethal voltages and precaution must be taken. | ||

*The switches that the keypad uses are still being manufactured today. They are C&K D6L90F1LFS and the D6L90F2LFS, they are the exact same. The difference being the force required to push the buttons. One takes 1.3 Newtons and the other 2 Newtons (Pic3). The keypad has 26 of them. Replacing them with new ones will fix the excessive bouncing. When de-soldering the switches one has to be careful of burning the PCB and lifting pads because the traces are very small. | |||

< | |||

:→ [[Media:D6L90F1LFS.pdf|Datasheet for D6L90F1LFS and D6L90F2LFS ]] | |||

< | <div style="clear: both"></div> | ||

==Conclusion== | ==Conclusion== | ||

[[Image:Bounce(3).jpg|thumb|left|250px|(Pic5) Restored keypad.]] | [[Image:Bounce(3).jpg|thumb|left|250px|(Pic5) Restored keypad.]] | ||

*It is not known how long this fix will last, but it makes the unit usable again. After the replacement the signal is now clean | * It is not known how long this fix will last, but it makes the unit usable again. After the replacement the signal is now clean (Pic5). | ||

[[Category: | [[Category:Instrument repair reports]] | ||

Latest revision as of 06:58, 19 January 2022

See also → Rebuilding 1230 keypad using 3D printer

Description

- The 1220, 1225 and 1230 have a keypad interface for controlling them. The switches are tactile switches with a small spring. Over time they start to become extremely "bouncy". This is due to a number of factors, some including corrosion and weakening springs. Over time this will lead to problems such as the keypad being less responsive and the analyzer registering multiple presses.

Picture 1 shows what the keypad is registering.

Fix

- WARNING! When taking the analyzer apart, users are at their own risk! The inside contains lethal voltages and precaution must be taken.

- The switches that the keypad uses are still being manufactured today. They are C&K D6L90F1LFS and the D6L90F2LFS, they are the exact same. The difference being the force required to push the buttons. One takes 1.3 Newtons and the other 2 Newtons (Pic3). The keypad has 26 of them. Replacing them with new ones will fix the excessive bouncing. When de-soldering the switches one has to be careful of burning the PCB and lifting pads because the traces are very small.

Conclusion

- It is not known how long this fix will last, but it makes the unit usable again. After the replacement the signal is now clean (Pic5).