S-4: Difference between revisions

(Added link to local copy of instruction manual) |

No edit summary |

||

| Line 1: | Line 1: | ||

{{Plugin Sidebar | {{Plugin Sidebar | ||

|manufacturer=Tektronix | |||

summary=Sampling Head | | |series=7000 and 3S series sampling heads | ||

image=Tek-s-4.jpg | | |type=S-4 | ||

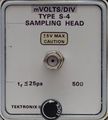

caption=S-4 head | |summary=Sampling Head | ||

|image=Tek-s-4.jpg | |||

introduced=1968 | | |caption=S-4 head | ||

discontinued=1990 | | |introduced=1968 | ||

manuals= | |discontinued=1990 | ||

|designers=George Frye | |||

|manuals= | |||

* [[Media:070-0896-01.pdf|Tektronix S-4 Instruction Manual, Revised OCT 1986 (OCR, PDF)]] | * [[Media:070-0896-01.pdf|Tektronix S-4 Instruction Manual, Revised OCT 1986 (OCR, PDF)]] | ||

* [http://w140.com/tek_s4.pdf Tektronix S-4 Manual, copyright 1969 (PDF)] | * [http://w140.com/tek_s4.pdf Tektronix S-4 Manual, copyright 1969 (PDF)] | ||

Revision as of 07:48, 13 August 2021

The Tektronix S-4 is a sampling head for 7000- and 3S-series samplers. It was designed by George Frye and introduced in 1968. It is the fastest of the S-series plug-in samplers.

Key Specifications

| Rise time | 25 ps (observed with S-50 or S-52, 35 ps) |

|---|---|

| Bandwidth | 14.5 GHz |

| Input impedance | 50 Ω (terminated SMA connector) |

| Input range | 1 Vp-p (operating) |

| Maximum input | ±5 V max. non-destructive |

| Noise | < 5 mV |

| Features |

|

Internals

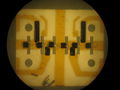

The S-4 sampling gate is based upon a traveling wave trapped-charge transmission line in which the sampling window is set by the propagation time of a pulse edge through a thick-film transmission line. This technique requires only a sharp pulse edge rather than a precise pulse width, which is harder to generate. The sampling diodes are housed in a special coaxial connector that provides a high bandwidth signal path.

To disassemble the sampler hybrid, first remove it from the sampler board as per the manual. Remove the input connector using a 7/32" wrench and remove the 20 dB attenuator with small pliers. The ceramic board is held to the housing using roll pins that can be pressed out with a 0.030" pin punch. The hybrid has six diodes, each about 0.75mm square. The cathodes are glued to the gold substrate with conductive epoxy and the anodes are wire-bonded (twice) over a gap to the next step in the strobe line. It appears that a standard beam-lead diode may fit across the gap but cleanly removing a failed diode without damaging the substrate would be quite difficult.

Links

- S-4 page @ amplifier.cd

- James R. Andrews, Comparison of Ultra-Fast Rise Sampling Oscilloscopes. Picosecond Pulse Labs App Note AN-2a, 1989