7000 series readout system

For the 7000-series scopes, a system was required to display the instrument state such as input range, time/div etc. alongside or within the display. Earlier solutions had included fiber-optical/mechanical displays to the side of the CRT such as those in the 576 Curve Tracer.

The design ultimately selected for the 7000 series was proposed and designed by Barrie Gilbert. It uses the CRT beam to display annotations in the same focal plane as the scope's main display.

Concept

Layout

A total of eight display fields can be superimposed on the CRT picture, four on top and four at the bottom. These are logically associated with the four possible slots in full-size mainframes, with the top field corresponding to the first channel, primary time base or primary function of a plug-in, and the bottom field corresponding to a second channel, delayed timebase, secondary function or unit label.

Readout modes

The standard mode of operation for the readout is free-running, i.e. in regular intervals that are asynchronous to the sweep, beam control is switched to the readout generator. In certain conditions, this can cause visible gaps in the signal display. When the readout intensity control is turned to minimum, this switching is disabled and the signal trace is not interrupted at all. (In the 7844 with its two physically separate beams, readout uses beam 2, and beam 1 is never interrupted.)

A sliding switch on the analog ROM readout board (internal to the scope) allows the operator to select "gate triggered" mode, in which the readout signal is produced only after a sweep has occurred. The advantage of this mode is that the beam is not interrupted while drawing the signal, however, if no sweep occurs there is no readout, and if the sweep is slow, the readout flickers.

In certain mainframes such as the 7844, 7904A and 7104, turning the display intensity control past the maximum intensity setting switches readout into pulsed mode. Depending on a second switch, readout occurs at the end of the sweep ("+ GATE") or when triggered by a back-panel "Graticule/Readout Single Shot" input. These scopes also have a "manual readout" button and similar controls for pulsed graticule illumination.

Scanning

The oscilloscope readout system produces a pulse train consisting of 10 successive negative-going pulses representing a possible character in a readout word, and is assigned a time-slot number corresponding to its position in the word. Each time-slot pulse is output at -15 V onto one of ten lines, labeled TS-1 through TS-10 (Time Slots 1 through 10), which are connected to the vertical and horizontal plug-in compartments.

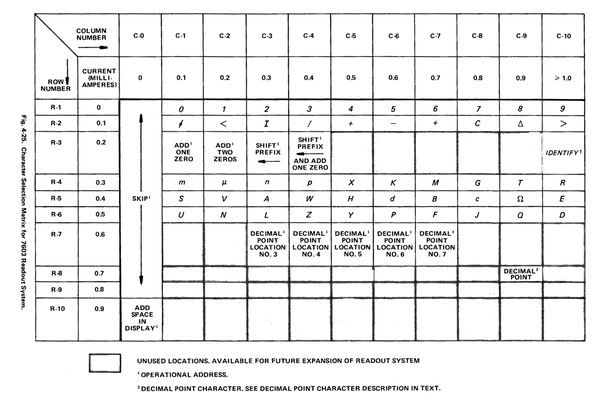

Two output lines, row and column, are connected from each channel (two channels per plug-in compartment) back to the oscilloscope readout system. Data is encoded on these output lines as a pair of ten-level analog current sequences (in 100 μA steps from 0 to 1 mA), which can address a matrix of 10 × 10 positions. In this matrix, rows 1, 2, 4, 5 and 6 correspond to characters whereas others are used to encode instructions:

In time slot 1, special operations can be requested that affect the display in later time slots. These commands are designed to simplify display changes required by external probes that request beam identification or change input sensitivity. The "Identify" command switches to an internal program displaying IDENTIFY instead of any encoded value. Command R3/C1 requests an additional zero to be added starting in time slot 5, R3/C2 adds two such zeroes, R3/C3 shifts the selected prefix one code to the left (i.e. p → n, n → μ, μ → m, m → space), and R3/C4 shifts the prefix and adds a zero. (See the encoding circuit of the 7A18 plugin for an example implementation.) It is also possible to request a decimal point to be drawn without losing display digits, by encoding row 7 commands in time slot 1.

Additionally R13 (row 13, selected by a row current of 1.3 mA) will produce a jump command by turning Q2153 off. This advances the display to the next channel, i.e. skips all following time slots of the current channel and their display.

Normally the readout will only display the channels of those plugins that are active as per the mode switches (P1018-P2118, channel inhibit), however individual plugins can override this by pulling the A35 ("override channel inhibit") line low. If the two channels of a plugin are inhibited, i.e. A35 is high at +15 V, two diodes (e.g. CR2163 and CR2162, with current sharing resistors) inject current into the A38/A37 line, effectively deleting the readout data by producing SKIP or space (C-0, R-x) instructions.

Plug-in circuit

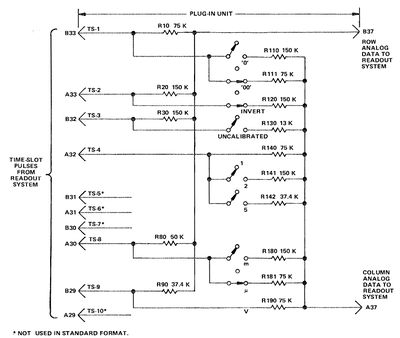

A plug-in encodes the desired read-out information either by connecting resistors between the output lines and the time-slot input lines, or by generating equivalent currents.

A simple plug-in such as a vertical amplifier will only require a small number of resistors and possibly diodes in addition to a suitably coded switch. It will use TS1 to encode the number of zeros, TS2 to display a down-arrow indicating an inverted input, TS3 to display ">" or "<" if the input is uncalibrated, TS4 for a digit, TS8 for a unit prefix like "μ" and TS9 for a unit like "V". The other slots are unused (see illustration).

Probe interface

Most 7000 series plugins have rings around the BNC input sockets that allow attached probes to interface with the readout system. The probe connector includes a contact pin connecting this ring. A resistor connected to ground encodes the probe attenuation, e.g. 11 kΩ indicates a ×10 probe and 6.8 kΩ a ×100 probe. If the probe includes an Identify switch at the tip, this connects the readout pin directly to ground.The plug-in circuit uses the shift instructions in time slot 1 to implement the change of range.

Complex plugins

The 7M13 plugin allows the user to encode arbitrary text and numbers plus an optional picture counter value, for photographic documentation.

Digital delay or counter plugins like the 7D11 or 7D14 display up to 8 digit counts in the top field and a unit (e.g. MHz) in the bottom field.

The 067-0905-99 "Readout Exerciser" is a test fixture for the readout system.

Implementation

Analog-ROM Readout Board

Character generation

The character generators are custom analog chips that provide X and Y output currents for ten characters of up to seven strokes (eight X/Y coordinate pairs) inscribing each character. The in-character coordinate points are selected through a triangular analog character scan signal, not a digital code, which in turn activates one of eight groups of three transistors each generating the X/Y output currents. Each of these groups is fed a constant emitter current (IE), and the distribution of this current to the three transistors is controlled by their different emitter areas. The first and second collectors provide X and Y currents respectively, the third ("Z") directs current to the substrate (IE - IX - IY - IZ = 0). Actually, the emitter area itself is not varied in the mask, but out of a fixed number of emitters of equal size, a certain number is connected on each transistor:

If the bases were controlled by a digital decoder, only one triplet of transistors would be active at any time and only points would be generated on the display. Instead, through an analog driving circuit, gradual cut-over is achieved, i.e. current from one group is reduced while that from the next group is increased, and a linear transition from the first to the second X/Y coordinate pair is displayed as a stroke on the CRT. The actual shape of the base drive voltages has great influence on the proper character rendering (this is explained at length in Gilbert's 1971 SSC paper).

Custom chips

- 155-0014-01 Analog to Decimal Converter

- 155-0015-01 Analog Data Switch

- 155-0017-00 Zero Logic Counter

- 155-0018-00 Zeros Logic

- 155-0019-00 Decimal Point and Spacing

- 155-0020-00 Output Assembler

- 155-0021-00 Timing Generator

- 155-0023-00 R-1 Character generator (Numerals 0 1 2 3 4 5 6 7 8 9)

- 155-0024-00 R-2 Character generator (Special Symbols ↓ < I / + - + C Δ >)

- 155-0025-00 R-4 Character generator (Prefixes m μ n p X K M G T R)

- 155-0026-00 R-5 Character generator (Letters S V A W H d B c Ω E)

- 155-0027-00 R-6 Character generator (Special Alpha U N L Z Y P F J Q D)

- 155-0038-01 D/A converter

7854

The 7854 contains a microprocessor controlled 40x16 character display generator which is also used to display plugin readout. The readout interface therefore contains only the column driver, multiplexer and A/D section but not the character generator - it only feeds readout data to the microprocessor.

EPROM-based Readout Board

Towards the end of the 7000 series lifespan, in the 2nd half of the 1980s, a re-designed readout board, Tek part number 670-8622, was introduced, in which the character generator is based on digital values stored in a 2732 EPROM instead of Gilbert's analog ROMs. This board was installed e.g. in the R7103 and 7904A and still used some of the Tek-made readout ICs like the timing generator. The design is similar to the readout mechanism in the 2465 series.

The number of display points was increased to up to 16 per character. The presence of this board can be detected from the outside by looking at the readout characters which are straight up but were italicized in the analog version (which was done the analog way too, by adding some 10% of the vertical signal to the horizontal channel). The character style itself is also different — for example, the "V" in the classic board has just two straight lines, whereas they are angled in the digital version.

Microcontroller-based Readout Board

Finally, from 1989/1990 on, a third generation readout board designed around an 80C31 micro-controller replaced the previous versions in the last series of 7104, R7103, R7844 and 7904A models (7623B to be confirmed.) This version no longer used any Tek-made special ICs, manufacture of which had been discontinued by that time. The board is part SMD, part through-hole. It is described in this version of the 7904A manual (pages 288 through 291 described the EPROM version above, while the 80C31 version is described on pages 380 through 391).

Literature

- Barrie Gilbert, Monolithic Analog READ-ONLY Memory for Character Generation, IEEE J. of Solid-State Circuits, 1971.

Links

- Repair of readout and installation of readout board in another scope (many photos, German text)

- Thread about probe readout details

Character code table

- A R5/C3

- B R5/C7

- C R2/C8

- D R6/C10

- E R5/C10

- F R6/C7

- G R4/C8

- H R5/C5

- I R2/C3

- J R6/C8

- K R4/C6

- L R6/C3

- M R4/C7

- N R6/C2

- P R6/C6

- Q R6/C9

- R R4/C10

- S R5/C1

- T R4/C9

- U R6/C1

- V R5/C2

- W R5/C4

- X R4/C5

- Y R6/C5

- Z R6/C4

- m R4/C1

- μ R4/C2

- n R4/C3

- p R4/C4

- d R5/C6

- c R5/C8

- 0 R1/C1

- 1 R1/C2

- 2 R1/C3

- 3 R1/C4

- 4 R1/C5

- 5 R1/C6

- 6 R1/C7

- 7 R1/C8

- 8 R1/C9

- 9 R1/C10

- ↓ R2/C1

- < R2/C2

- / R2/C4

- > R2/C10

- Δ R2/C9

- + R2/C5 or R2/C7

- – R2/C6

- Ω R5/C9