Micro-channel plate CRT: Difference between revisions

No edit summary |

No edit summary |

||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

trace, which is needed particularly at high sweep rates. Typically it sits directly behind the face of the CRT. It requires its own bias voltage. | trace, which is needed particularly at high sweep rates. Typically it sits directly behind the face of the CRT. It requires its own bias voltage. | ||

The electron beam passes through the deflection plates before it hits the micro-channel plate, which consists of parallel channels | [[File:Micro-channel plate diagram.jpg|600px|thumb|right|Structure of an MCP CRT (click to enlarge)]] | ||

offset at a slight angle to the beam. The inside walls of these channels are coated with resistive material, with an acceleration voltage | The electron beam passes through the deflection plates before it hits the micro-channel plate, which consists of parallel channels offset at a slight angle to the beam. | ||

on the order of 1 kV applied between back and front of the plate | The inside walls of these channels are coated with resistive material, with an acceleration voltage on the order of 1 kV applied between back and front of the plate. | ||

MCP amplification deteriorates in proportion to total charge passed per channel or unit of area, making them | Due to the offset angle, electrons entering a channel will hit its wall, where they initiate a cascade of secondary electron emission like in a photomultiplier. | ||

particularly prone to a form of burn-in. | At the exit of the channels, a final acceleration voltage propels the beam across a small gap toward the CRT's phosphor coating. | ||

In a typical MCP CRT like the [[T7100]], the channels have 25 μm diameters. | |||

MCP amplification deteriorates in proportion to total charge passed per channel or unit of area, making them particularly prone to a form of burn-in. | |||

Careful biasing along with beam current/time limiting mechanisms are necessary to achieve the full life time. | Careful biasing along with beam current/time limiting mechanisms are necessary to achieve the full life time. | ||

| Line 15: | Line 16: | ||

MCP tubes are used in the following Tektronix products: | MCP tubes are used in the following Tektronix products: | ||

* [[7104]] | * [[7104]]/[[R7103]]: [[T7100]] | ||

* [[ | * [[2467]]/[[2467B]]: [[T2467]] | ||

* [[ | * [[11302]]/[[11302A]]: [[T7707]] | ||

* [[7250]] (in the [[scan converter]] tube, not the visible CRT) | * [[7250]] (in the [[scan converter]] tube, not the visible CRT) | ||

==Links== | ==Links== | ||

* [ | * [[wikipedia:Microchannel_plate_detector|Micro-channel plate detector]] @ Wikipedia | ||

* [https://www.youtube.com/watch?v=v9KaTgChudw Tektronix 2467B "Bright Eye (tm)" Oscilloscope promotional video] | * [https://www.youtube.com/watch?v=v9KaTgChudw Tektronix 2467B "Bright Eye (tm)" Oscilloscope promotional video] | ||

* [https://apps.dtic.mil/sti/pdfs/ADA195556.pdf AD-A195 556], ''Development and Manufacture of the Microchannel Plate (MCP)''. US Army report, 1988. | |||

* [http://www.dmphotonics.com/MCP_MCPImageIntensifiers/microchannel_plates.htm Microchannel Plates] – Detailed information @ DelMar Photonics | |||

===Patents=== | |||

* [[Patent US 5134337A|US Patent 5,134,337]], ''Projection lens assembly for planar electron source''. Kongslie et al., 1992. | |||

* [[Patent US 4931704A|US Patent 4,931,704]], ''Ultrafast sampling oscilloscope''. Alfano et al., 1990. | |||

* [[Patent US 4956548A|US Patent 4,956,548]], ''Ultrafast oscilloscope''. Alfano et al., 1990. | |||

* [[Patent US 4365150A|US Patent 4,365,150]], ''Gain stabilized microchannel plates and MCP treatment method''. Roger S. Bateman, 1982. | |||

* [[Patent US 4752714A|US Patent 4,752,714]], ''Decelerating and scan expansion lens system for electron discharge tube incorporating a microchannel plate''. J.Sonneborn, [[Ken Hawken]], 1988 | |||

* [[Patent US 4147988A|US Patent 4,147,988]], ''Channel multiplier plate CRT scan converter and scan conversion method''. [[Dennis Hall]], 1979. | |||

[[Category:Micro-channel plate CRTs]] | [[Category:Micro-channel plate CRTs]] | ||

Latest revision as of 07:37, 7 June 2024

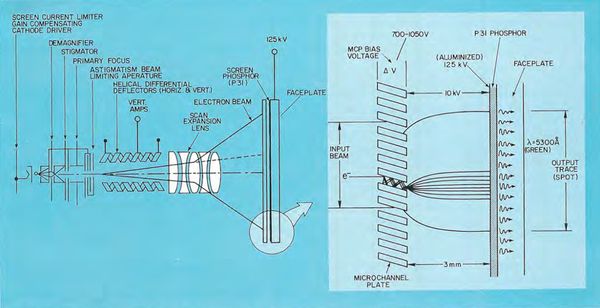

The Micro-channel plate (MCP) is a form of secondary electron multiplier that can be included in a CRT to improve the brightness of the trace, which is needed particularly at high sweep rates. Typically it sits directly behind the face of the CRT. It requires its own bias voltage.

The electron beam passes through the deflection plates before it hits the micro-channel plate, which consists of parallel channels offset at a slight angle to the beam. The inside walls of these channels are coated with resistive material, with an acceleration voltage on the order of 1 kV applied between back and front of the plate.

Due to the offset angle, electrons entering a channel will hit its wall, where they initiate a cascade of secondary electron emission like in a photomultiplier. At the exit of the channels, a final acceleration voltage propels the beam across a small gap toward the CRT's phosphor coating. In a typical MCP CRT like the T7100, the channels have 25 μm diameters.

MCP amplification deteriorates in proportion to total charge passed per channel or unit of area, making them particularly prone to a form of burn-in. Careful biasing along with beam current/time limiting mechanisms are necessary to achieve the full life time.

The MCP enables an improved system bandwidth overall.

MCP tubes are used in the following Tektronix products:

- 7104/R7103: T7100

- 2467/2467B: T2467

- 11302/11302A: T7707

- 7250 (in the scan converter tube, not the visible CRT)

Links

- Micro-channel plate detector @ Wikipedia

- Tektronix 2467B "Bright Eye (tm)" Oscilloscope promotional video

- AD-A195 556, Development and Manufacture of the Microchannel Plate (MCP). US Army report, 1988.

- Microchannel Plates – Detailed information @ DelMar Photonics

Patents

- US Patent 5,134,337, Projection lens assembly for planar electron source. Kongslie et al., 1992.

- US Patent 4,931,704, Ultrafast sampling oscilloscope. Alfano et al., 1990.

- US Patent 4,956,548, Ultrafast oscilloscope. Alfano et al., 1990.

- US Patent 4,365,150, Gain stabilized microchannel plates and MCP treatment method. Roger S. Bateman, 1982.

- US Patent 4,752,714, Decelerating and scan expansion lens system for electron discharge tube incorporating a microchannel plate. J.Sonneborn, Ken Hawken, 1988

- US Patent 4,147,988, Channel multiplier plate CRT scan converter and scan conversion method. Dennis Hall, 1979.