432: Difference between revisions

No edit summary |

No edit summary |

||

| Line 56: | Line 56: | ||

Tek_432_internal_15.jpg|A view of the contact fingers underneath the capacitor shaping blocks. Each channel has 8 NC and 8 NO fingers (the other half are on the bottom). These are easy to reach and clean as described. So each channel has a total of 20 contact fingers to clean. | Tek_432_internal_15.jpg|A view of the contact fingers underneath the capacitor shaping blocks. Each channel has 8 NC and 8 NO fingers (the other half are on the bottom). These are easy to reach and clean as described. So each channel has a total of 20 contact fingers to clean. | ||

</gallery> | </gallery> | ||

{{Custom ICs|432}} | |||

[[Category:400 series scopes]] | [[Category:400 series scopes]] | ||

[[Category:Specifications needed]] | [[Category:Specifications needed]] | ||

Revision as of 01:55, 22 November 2021

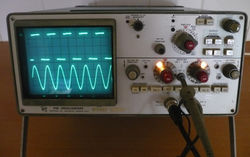

The Tektronix 432 is a 25 MHz dual-trace portable solid-state oscilloscope.

There is also a rack-mount version, the R432.

Each 432 vertical signal path starts with the coupling switch, then a rotary cam attenuator, then a dual-JFET source-follower buffer amp, then a 155-0050-00 differential amplifier (switched to 155-0050-01 after serial number B239999).

The vertical and horizontal output amplifiers are fully discrete, using silicon bipolar transistors.

Triggering is done by a 4.7 mA tunnel diode that is fed by a discrete trigger amplifier.

The 432 consumes 55 watts maximum and weighs 20 pounds.

P31 phosphor was standard. P7 was also available.

Specifications

please add

Links

- Ken Matheson, Servicing the 432/434 Oscilloscopes. In Tekscope Vol. 4 No. 5, 1972

- Handle Replacement Modification Kit

Pictures

-

-

-

-

This shows the area around the BNC input connectors for channels 1 and 2. This photo was taken when the owner was cleaning the vertical gain rotary switches which had become flaky after 45 years.

-

View from the rear. The vertical gain attenuator switches are under the metal covers.

-

When the metal covers are removed, one can see the shaping/compensation capacitors. These can be unplugged, each one has 6 legs.

-

Another view of the shaping capacitors. Work on one channel at a time to avoid mixing these up. Carefully clean the legs with isopropal alcohol and paper towels.

-

In order to access the rotary gain switch fingers, one must first remove these BNC connectors, which means unsoldering the central wire (connects to a resistor/inductor feed-through) plus a debouce capacitor and lead going to the x1 x10 indicator lights.

-

Close up view of BNCs

-

Close up view of BNCs

-

Close up view of BNCs. These need to be unsoldered for removal, but nothing else must be unsoldered to access/clean the vertical gain rotary switch.

-

View of the input preamp. This board needs to be unplugged only, but not removed or unsoldered. It has four 2-pin connectors. Then it can be removed, still attached to the compensation capacitor carriers.

-

Lifting off the assembly consisting of the 2 compensation capacitor carrier plus the vertical preamp board plus the push-button switch board for CH1/CHOP/ALTERNATE/CH2. The switch board has two plug connectors below that must be removed. It helps to have long fingers or a good pair of needle nose pliers.

-

Second view under the assembly being removed.

-

The rotary switches exposed. Each one has four contact fingers underneath. They are cleaned using small (5mm) wide strips of paper soaked in isopropanol alcohol (2-propanol).

-

One can just see the four contact fingers peeking out. You can get paper under them using small tweezers. Patience and calm are required.

-

A view of the variable-gain potentiometers. Note that the bodies are both cracked in the same place. Both had been noisy, but the noise was largely eliminated by sweeping them back and forth a dozen times. That may have scrubbed off the oxide.

-

A view of the contact fingers underneath the capacitor shaping blocks. Each channel has 8 NC and 8 NO fingers (the other half are on the bottom). These are easy to reach and clean as described. So each channel has a total of 20 contact fingers to clean.

Custom ICs used in the 432

| Page | Model | Part nos | Description | Designers | Used in |

|---|---|---|---|---|---|

| 155-0028-00 | M018 | 155-0028-00 • 155-0028-01 • 155-0042-00 • 155-0042-01 • 155-0042-02 • 155-0042-03 | Miller integrator and delay pickoff | Joe Burger | 5030 • R5030 • 5031 • R5031 • 1401 • 1401A • 1480 • 1481 • 1482 • 1485 • 26G1 • 26G2 • 26G3 • 314 • 335 • 432 • 434 • 4701 • 5B10N • 5B12N • 5B31 • 5B40 • 5B42 • 5S14N • 7B52 • 7B53A • 7B53N • 7L12 • 7L13 • 7L14 • 7L18 • 7S14 • AN/USM-281C • RG501 • Telequipment D63 • Telequipment DM63 |

| 155-0048-01 | M052F | 155-0048-00 • 155-0048-01 • 155-0055-00 • 155-0055-01 | trigger sweep | Dave Allen | 211 • 212 • 213 • 214 • 432 • 433 • 5B12N • 5B13N • 5L4N • 603 • 604 • 605 • 606 • 606A • 607 • 624 • SC501 • R7912 |

| 155-0050-01 | M065 | 155-0050-00 • 155-0050-01 | differential vertical preamplifier | Bert tenKate | 432 • 434 |

| 155-0051-00 | 155-0051-00 | 155-0051-00 | Z-axis and HV regulator | 432 • 434 |